Information for Ordering and Using

|

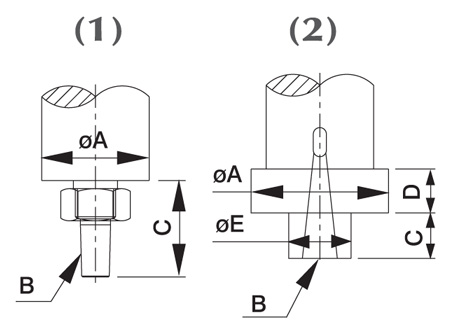

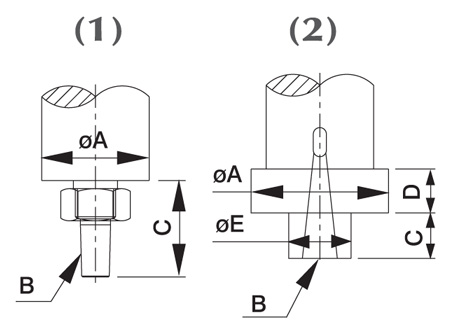

1. Machining sizes, hole diameters and materials.

2. Machining type: drilling tapping reaming.

3. Drilling machine type and motor horsepower.

Spindle nose of drilling machine

| A |

B |

C |

D |

D |

| Dia of quill |

Spindle taper |

Spindle length |

Collar length |

Spindle diameter |

| |

|

|

|

|

|

| |

¡iCaution when using multi-spindle head¡j |

|

|

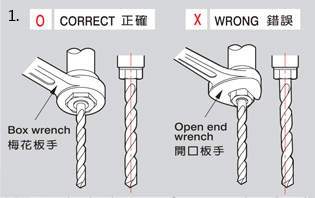

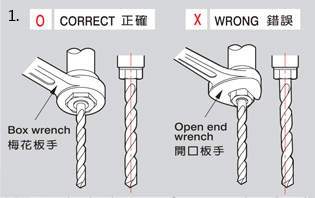

Use correct box wrench to tighten or loosen

collet. Do not use an open end wrench for

this purpose. Failure to comply may cause

damage on the collet due to uneven

tightening or loosening force or inaccurate

chucking of cutting tool. |

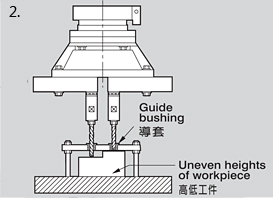

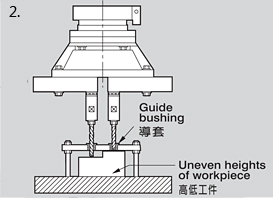

Guide bushing equipped on the workpiece

not only upgrades machining accuracy, but

also ensure the service life of the spindle.

In case workpiece has uneven heights of

surfaces, you need to lower the drill until

they touch the various surfaces of the

workpiece before tightening the cutting

tools. Then you can tighten the cutting

tools securely. |

|

|

When mounting the multiple

spindle drilling head, place

three leveling blocks under it.

Have them aligned with

spindles, and press it until it

reaches the main tooth. |

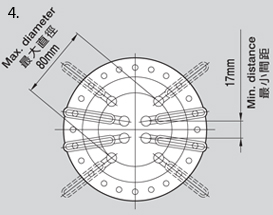

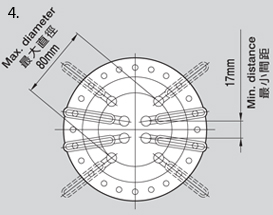

Minimum distance and maximum diameter diagram. |

|

| |